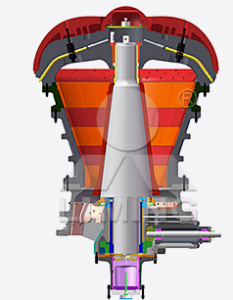

When the hydraulic cylinder is lifted by pressure, the shaft pin is first cut off, and the crusher stops running, so as to prevent other parts of the machine from being damaged. The weakened section shaft pin on the pulley is the safety device of the gyratory crusher. When large pieces of non-broken material enter the crushing cavity, the large bevel gear with three thrust discs fixed on the eccentric shaft sleeve rotates, so that the moving cone performs a swinging motion. In addition, between the large bevel gear and the center sleeve, the rotation direction of the movable cone is opposite to the rotation direction of the eccentric sleeve. This self-rotating motion makes the particle size of the crushed products more uniform, and makes the movable cone liner wear evenly. The movable cone generates a friction torque M due to the crushing force.

Because the friction force F>F (friction coefficient fa> the friction torque M on the main shaft can make the moving cone rotate around its own axis, and its direction is the same as the rotation direction of the eccentric bushing when running under load, in addition to the friction torque between friction and Around the self-rotating motion of this axis, the motion situation is similar to the gyro, and it is all gyratory motion.When the crusher runs without load, the difference between the action hydraulic gyratory crusher and the above-mentioned gyratory crusher is: or at the support ring of the main shaft suspension point Install the hydraulic cylinder, make the mass sleeve of the moving cone, and install a dust-proof device at the bottom of the moving cone.

The function of the conical nut is to adjust the device. Rotate the conical nut to make the main shaft and the movable cone rise or fall, so as to adjust the size of the discharge port to break the material. At the same time, the crushed material moves downward under the action of its own weight until it is discharged from the discharge port. In order to prevent dust from falling into the eccentric shaft sleeve during discharging, a dust-proof device is required. When the eccentric bushing rotates, the main shaft of the movable cone takes the suspension point on the beam as the cone vertex for conical motion, and the function of the transmission mechanism is to transmit power. When the motor rotates, the center line of the fixed hole and the axis of the gyratory crusher are slightly eccentric through the V-belt pulley, the coupling, and the small bevel gear. The inner and outer surfaces of the eccentric bushing should be cast (or welded) with a layer of babbitt alloy, and the outer support ensures that the bushing rolls along the support ring and the conical bushing, which meets the requirements of the main shaft movement. The lower end of the main shaft is inserted into the eccentric hole of the eccentric sleeve, and the entire mass of the main shaft and the movable cone is supported by the conical bearing in the beam.