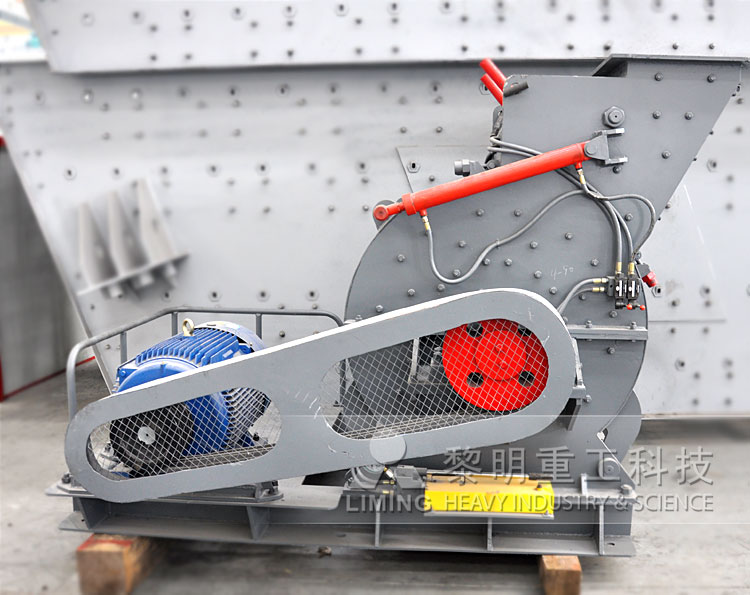

Hammer Crusher is also called Hammer Mill ,It is one of our patents with the latest technology .

Hammer Mill’s Overview:

The European Type Hammer Crusher is suitable for secondary and fine crushing all kinds of rocks with compressive strength less than 320MPa. European Type Hammer Crusher is widely used in mining, building materials, chemical industry, metallurgy, cement, ceramic, refractory industry and so on.

Hammer Mill’s Features:

1. World-level manufacturing technology is adopted, and highest-level raw material is used.

2. Central lubricating device are installed on the machine, so the bearing is easy to be lubricated.

3. Adjustment of the discharge part is more convenient.

The adjustment methods: gasket adjustment, hydraulic assistant adjustment, wedge block and wedge hydraulic adjustment.

4. More advanced movable jaw assembly lengthens life of crusher.

Movable jaw assembly is made from cast piece with high-quality, is driven by two large flying wheels which are made from cast steel. Moreover, heavy eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher extremely reliable.

5. Integral cast steel structure is adopted for bearing seat. Integral cast steel bearing matches well with the crusher frame, at the same time, radial strength of the bearing seat is highly strengthened. However, the separate bearing seat does not have this advantage.

6. Finite element analysis technology is adopted to make the crusher much stronger.

7. Crusher chamber adopts “V” structure which could make actual feed width comply with the nominal one.

8. Bearing with larger model and higher load are used. All JC jaw crusher is equipped with larger bearing compared with same model of normal jaw crusher. Its higher load capacity and effective oil seal will lengthen the life of bearing.

9. A newly designed tooth-shape side plate, makes the available area of jaw plate longer, and enhances the capacity.

10. Pressing bar and support type are used to fix jaw plate.

11. Heavy type protecting plate is intalled for bearing seat, accidental damage of bearing seat is avoided.

12. Supporting bar under jaw plate protects movable jaw and frame from being worn down.

Hammer Mill’s Highlights:

(1) High capacity, high crushing ratio.

(2) Simple structure, easy maintenance, easy operation.

(3) Even output granularity and electricity-saving.

(4) The water content of materials is less than 10% – 15%.

Hammer Mill’s Working principle:

European Type Hammer Crusher mainly includes case, rotor, iron bearing, grate bars and other components. There are two parts in case: the upper one and lower one which are welded after cutting. The remaining parts are connected by bolts. Inside the case, there is high manganese steel liner which can be replaced after wear and bear. European Type Hammer Crusher is installed on an array of spindles which forms the rotor together with rotary table and axis. The rotor rotates through motor and V-belt driven spindle. The hammer stretches around as the centrifugal force generated by rotation, in that way, bulk materials feed into the crushing chamber and are crushed by the high-speed movement. The standard stones pass from the grate bars below and for those not standard will again be crushed in the case till they can pass from the grate.

Hammer Mill’s Applications:

1. European Type Hammer Crusher is used in building materials

Building materials industry use hammer crusher broken, its life and clinker hammer head by manganese steel qualitative most after made, use the series is wear faster, broken malpractice ability low, and the biggest drawback is deformation, otherwise, it will be spoilt by stuck influence equipment safety. In order to increase the wear-resisting material factory service life of hammer head of consumption, reduce metal by engineering and technical personnel countless times in the market using reflect good, recognized by the vast number of users and praise.

2. Hammer Crusher can be used in gypsum board industry

In gypsum board industry, the rotor on drying Hammer Mill can break up and throw gypsum slag, whose water content is no more than 28%. During this process, the gypsum slag exchanges the heat with the intake hot air of 550℃,and then the max water content of the material is 1%. European Hammer Crusher adopts reasonable and reliable process technology, high-quality material and advanced automated processing equipment, which ensures the reliable and steady operation, and convenient maintenance.

3. Hammer crusher can be applied in road construction

Pulverized limestone is used as aggregate—the solid base for many roads. Limestone is a sedimentary rock composed largely of calcite, calcium carbonate. Limestone often contains variable amounts of silica or siliceous skeletal fragment, as well as varying amounts of clay, silt and sand sized terrestrial detritus carried in by rivers. Our hammer crusher can be used to crush limestone into the required sizes

Hammer Mill’s Library:

1. European Hammer crusher installation and commissioning

(1) According to raw materials, selecting the terrain before installation.

(2)The machine should be fixed in concrete, leaving a discharge trough when designing foundations and its slope is not less than 50 °, but the user can also decide according to the feeder and transport equipment.

(3) The motor should be installed in the opposite direction of feed opening.

(4) The electrical equipment should be installed in the convenient place.

(5) Examine whether all the fasteners are completely fastness before commissioning.

(6)Check whether metal or other not easy broken debris drop into the body.

(7) Check whether there is proper lubrication in the bearing.

(8) Rotating the rotor by hand, to see whether it is normal, and friction phenomenon, confirmed the movement is unimpeded before empty starts, a half hour later, if no noise, no vibration, bearing temperature can not exceed 30 ℃, and then you can load commissioning.

2. European Hammer Crusher failure and exclusion

(1) Bearing overheating:

Reasons: lack of grease; too much grease; grease filthy degenerate; bearing damage.

Remedy: filling right amount grease; in the bearing grease should be occupied within 50% of its space capacity; cleaning bearings; replacement of grease; replace the bearings.

(2)The particle size is too large:

Reasons: excessive wear of the hammer; screening fracture.

Remedy: Replace the hammer; replace the screen bar.

(3) Reduced production:

Reasons: screening gap is blocked; feeding uneven.

Remedy: parking, cleaning up the obstruction in the gap; adjust feeding agencies.

(4)Elastic couplings produce percussion sound:

Reasons: pin roll loosening; elastic ring wear;

Remedy: parking, and tighten pin nut; replace the elastic ring.

(5) The machine internally generated percussion sound:

Reasons: non-broken materials fall into the machine; liner fasteners are loose, hammer impact on the liner; hammer or other parts broken.

Remedy: parking, cleaning up the crushing chamber; check the liner fastening and the gap between the hammer and the screen; replace broken parts.

(6) The machine vibration

Reasons: when replacing hammer cone or due to hammer wear, so that static balance of the rotor is not up to standard; hammer broken, rotor imbalance; pin bending and breaking; bolt loose.

Remedy: Remove the hammer, select the hammer by weight, so that the total of each shaft hammer is equal to the total weight of relative shaft hammer, meet the requirements of static equilibrium; replacement hammer; replacement pin; Welding repair or replacement; fastening bolts.

3. European Hammer Crusher maintenance and adjustments

(1) Coupling on the elastic sleeve is found damaged, should be replaced.

(2) The adjustment of product size can change the style of Article sieve, or screen shall be installed in the screen frame embedded at both ends of tank fill block to change the screen section of the gap.

(3) Granularity can be adjusted by rotating the eccentric shaft to adjust the hammer and the gap between the screen sections.

(4) European Hammer Crusher, if sudden strong vibration, immediately stop and identify the cause and eliminate, and then start hammer crusher, hammer in the side impact part of the wear and tear, you can reverse the other side to use.

(5) Assembly or replacement of a hammer, must maintain the balance of the rotor. Hammer axis of each row of the total mass should correspond to hammer axis equal to the total mass of the total deviation of no more than 1 00g. Not a single hammer mass deviation ± 0.5kg.