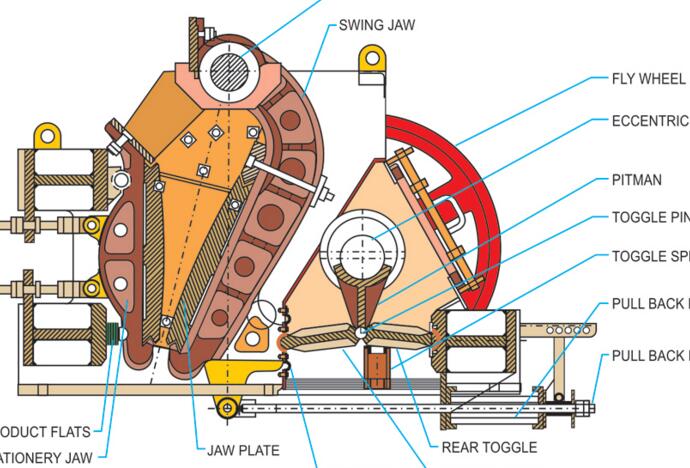

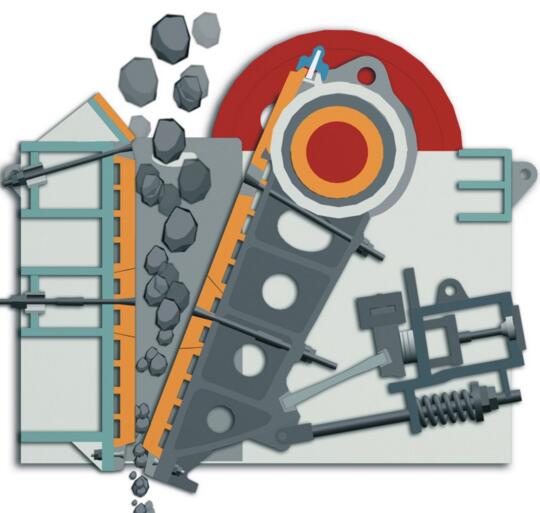

Jaw crusher known as jaw broken by a movable jaw and static jaw jaw composed of two crushing chamber to simulate the movement of animals two jaw crusher complete material crushing operations. For a variety of ores and bulk materials of medium-grained broken, the maximum compressive strength of the material to be broken for 320Mpa. But in the course, there will be loss problem, how to reduce the abrasion of jaw crusher it?

First, due to the strength of the lead lining crushing chamber force is not uniform, and ultimately can lead to uneven wear lining, affecting the normal operation of the crusher. Therefore, to improve the efficiency of the crusher to improve the forces parts of the equipment, give full play to the laminate broken during crushing functions in the production process should try to ensure uniformity requirements to feed material strength.

Second, the jaw crusher in bulk materials must meet the requirements can be broken, to the maximum material strength to strength in the jaw crusher can handle it. In addition, in the process of crushing, crushing chamber should prevent iron and other non-broken material into them. Heavy learned from Red Star, after crushing the material when mixed together, there are a variety of materials strength inequality, high strength material will protect small strength material, thereby reducing the strength of the material crushing small probability and product size.

Third, when the jaw crusher can not break into the cavity (such as iron, steel balls, etc.), for the maintenance of equipment important parts are not damaged, the thrust plate to be taken after a jaw crusher the insurance component. When non-broken material into the crushing chamber, the device generates overload phenomenon, crushing force to cause the thrust plate thrust plate fracture or a combination thrust plate screws cut, machine end of the work, played a role as insurance. This can reduce the loss of jaw crusher.