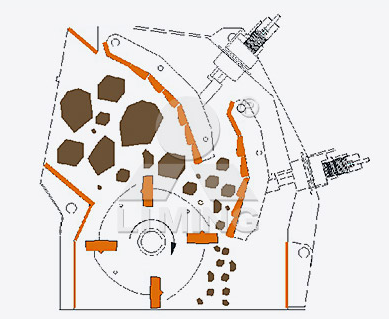

The structure of jaw crusher is relatively simple, mainly composed of frame, DS working mechanism, transmission mechanism, adjustment device, safety device and lubrication system. The following takes the 900mm × 1200mm simple pendulum jaw crusher (Figure 1) as an example to briefly introduce its structure.

1) Rack

There are two types of jaw crusher: integral frame and combined frame. The overall frame is generally made of castings or steel parts. Domestic small and medium-sized crushers mostly use integral frame. The combined frame is composed of multiple pieces of cast iron or welded parts connected by dowels or bolts. It is mainly used for large jaw crushers that are difficult to transport (such as crushers for underground use) or difficult to process and manufacture.

2) Work organization

The working mechanism of the jaw crusher (ie the crushing cavity) consists of a fixed jaw (ie the front wall of the frame in Figure 1) and a movable jaw 5. Both jaws are lined with linings 2 and 6 made of manganese steel, and the linings are fixed on the jaws with bolts and wedges. Since it directly participates in the crushing, in order to improve the crushing effect, the surface of the lining plate has longitudinal corrugations, and the unevenness is opposite. At present, the tooth shape of the lining plate of the domestic jaw crusher is mostly triangular and trapezoidal. The surfaces are all straight strips. With the application and development of computer, the design of tooth shape has been developed from the traditional test method and empirical method to the use of computer to optimize the design to obtain the best crushing effect.

The working principle of jaw crusher

Jaw crushers have a long history of development. The jaw crushers produced and designed by our company include PE series jaw crushers, HJ series jaw crushers, and PEW series jaw crushers. They can be used as the primary of the mine crushing industry. Crusher, crushing materials with relatively large volume.

Although the structure of the jaw crusher is different, its working principle is the same, that is, the material is crushed by the periodic reciprocating motion of the movable jaw. In the process of swinging the movable jaw to the fixed jaw around the suspension mandrel, the material between the two jaw plates will be crushed, split and bent. At the beginning, the pressure is small, so that the volume of the material is reduced, and the materials are close to each other and squeezed tightly; when the pressure rises beyond the strength that the material can bear, it will break. On the contrary, when the movable jaw leaves the fixed jaw and swings in the opposite direction, the material moves downward by its own weight. Each periodic movement of the movable jaw causes the material to be crushed once and sent down a certain distance. After several cycles, the crushed materials are discharged from the discharge port.